What is cold plasma, and why is it transforming modern medicine? Cold plasma is a partially ionized gas that operates at near room temperature, containing reactive species, electrons, and ions that can safely interact with biological tissues for therapeutic purposes[1]. This revolutionary fourth state of matter has emerged as a breakthrough technology in medical applications, offering non-invasive treatment options for wound healing, pain management, and tissue regeneration.

Unlike traditional thermal plasma that requires extreme temperatures, cold atmospheric plasma (CAP) maintains temperatures below 40°C, making it safe for direct contact with human skin and tissues[2]. This unique characteristic has opened new possibilities in medical treatments, from chronic wound care to cancer therapy.

Understanding Cold Plasma Technology

What Makes Cold Plasma Different from Traditional Plasma?

Cold plasma represents a unique state of matter where gas molecules become partially ionized without generating excessive heat. This non-thermal plasma contains a complex mixture of reactive oxygen species (ROS), reactive nitrogen species (RNS), electrons, ions, and electromagnetic radiation[3].

The key distinction lies in the temperature differential between electrons and heavy particles. While electrons reach temperatures exceeding 10,000K, the gas temperature remains close to room temperature, creating what scientists call “non-equilibrium plasma”[4].

How Is Cold Plasma Generated?

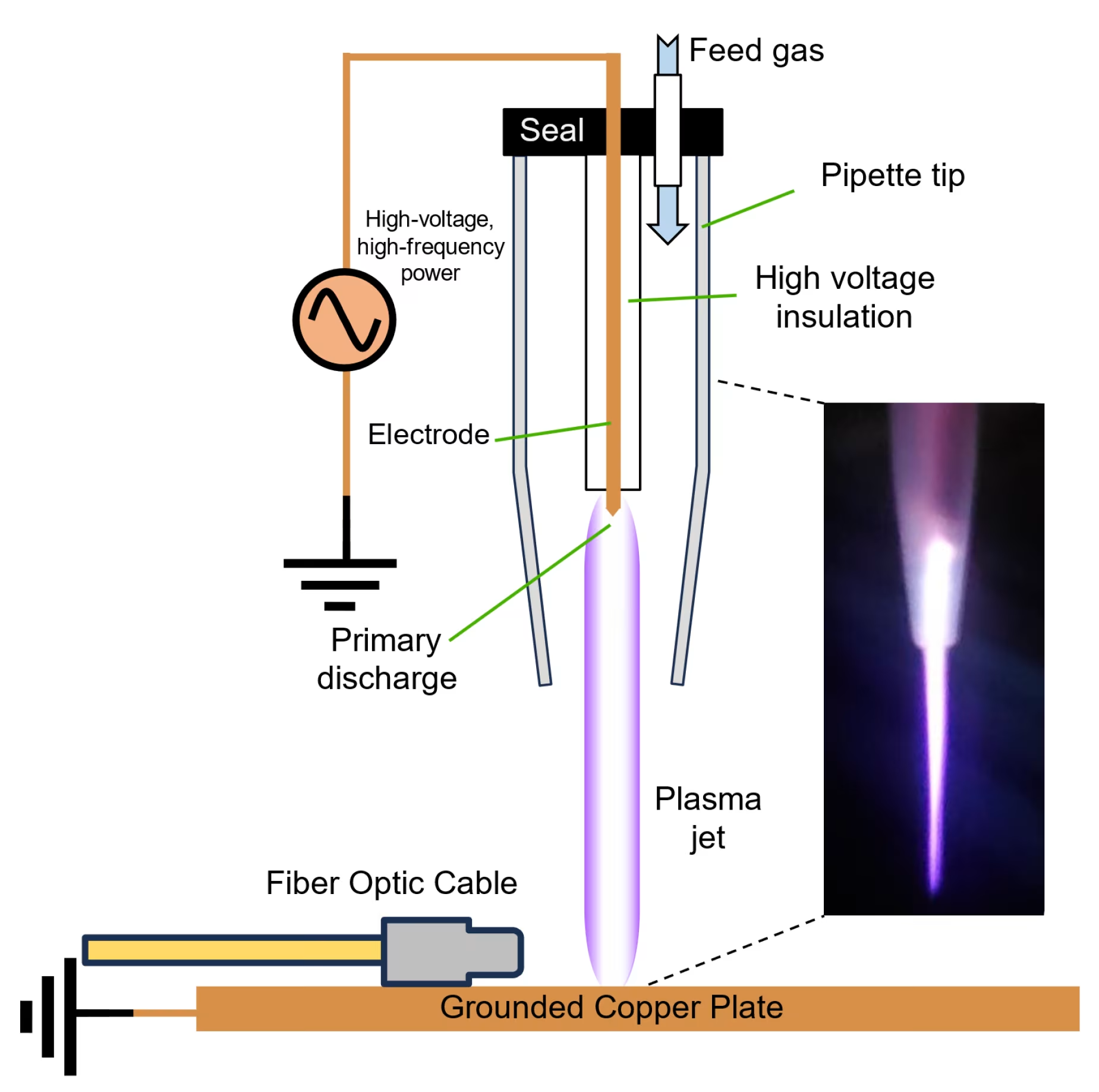

Cold plasma generation typically involves applying electrical energy to gases at atmospheric pressure. The most common method uses dielectric barrier discharge (DBD), where high-voltage alternating current creates plasma between electrodes separated by a dielectric material.

The process involves three critical steps:

- Gas Ionization: Electrical energy breaks molecular bonds in air or noble gases

- Reactive Species Formation: Ionized particles interact with surrounding molecules

- Controlled Delivery: The plasma stream is directed toward the treatment area

Scientific Mechanisms Behind Cold Plasma Therapy

Reactive Oxygen and Nitrogen Species Production

Cold plasma generates numerous bioactive compounds that interact with biological systems. The primary therapeutic agents include:

Reactive Oxygen Species (ROS):

- Hydroxyl radicals (OH)

- Hydrogen peroxide (H₂O₂)

- Superoxide anions (O₂⁻)

- Ozone (O₃)

Reactive Nitrogen Species (RNS):

- Nitric oxide (NO)

- Nitrogen dioxide (NO₂)

- Peroxynitrite (ONOO⁻)

- Nitrous acid (HNO₂)

These reactive species trigger various cellular responses depending on their concentration and exposure time[5]. Low concentrations promote cell proliferation and tissue healing, while higher concentrations can induce controlled cell death in pathogenic organisms or abnormal tissues.

Nitric Oxide vs Reactive Oxygen Species

One of the pioneering medical devices applying cold plasma therapy is the Mirari Cold Plasma system, developed by General Vibronics and brought to market by Mirari Doctor. It utilizes nitric oxide (NO) instead of traditional ROS-based systems to promote safe, non-thermal healing[6].

Nitric oxide offers several advantages over traditional ROS-based approaches:

- Enhanced biocompatibility: NO naturally occurs in the body as a signaling molecule

- Reduced oxidative stress: Less cellular damage compared to high-ROS systems

- Improved tissue healing: NO promotes vasodilation and angiogenesis

- Better patient tolerance: Minimal side effects and discomfort

Technical Specifications of Cold Plasma Systems

| Parameter | Range/Value | Clinical Significance |

|---|---|---|

| Operating Temperature | 25-40°C | Safe for direct tissue contact |

| Frequency Range | 50 Hz – 100 kHz | Determines penetration depth and energy delivery |

| Power Output | 2-12W | Controls treatment intensity |

| Treatment Duration | 30 seconds – 15 minutes | Varies by condition and device |

| Reactive Species Density | 10¹⁵-10¹⁷ particles/cm³ | Determines therapeutic efficacy |

| Nitric Oxide Production | 10-100 ppm | Key therapeutic agent in advanced systems |

Clinical Applications and Benefits

Wound Healing and Tissue Regeneration

Cold plasma has demonstrated remarkable efficacy in accelerating wound healing processes. Clinical studies show that plasma treatment can reduce healing time by 30-50% compared to conventional methods[7].

The healing mechanisms include:

- Enhanced angiogenesis: Formation of new blood vessels

- Increased cell proliferation: Faster tissue regeneration

- Improved collagen synthesis: Better wound strength and appearance

- Reduced inflammation: Faster resolution of inflammatory responses

Antimicrobial Effects

Cold plasma exhibits broad-spectrum antimicrobial activity against bacteria, viruses, fungi, and even antibiotic-resistant strains like MRSA[8]. The antimicrobial mechanisms involve:

- Cell membrane disruption: ROS damage bacterial cell walls

- DNA damage: Reactive species interfere with genetic material

- Protein denaturation: Essential enzymes become non-functional

- Biofilm destruction: Penetration through protective bacterial layers

Pain Management Applications

Recent research has explored cold plasma’s potential in pain management. The Mirari Cold Plasma system demonstrates promising results in treating various pain conditions through nitric oxide-mediated pathways[9].

Pain relief mechanisms include:

- Nerve signal modulation: Altered pain transmission pathways

- Inflammation reduction: Decreased inflammatory mediators

- Improved circulation: Enhanced tissue oxygenation

- Muscle relaxation: Reduced tension and spasms

Clinical Benefits and Treatment Outcomes

| Application Area | Treatment Duration | Session Frequency | Reported Outcomes |

|---|---|---|---|

| Chronic Wounds | 2-5 minutes | 3x weekly | 70-90% healing acceleration |

| Acute Wounds | 30-120 seconds | Daily | 40-60% faster closure |

| Skin Infections | 1-3 minutes | 2x daily | 99.9% pathogen reduction |

| Pain Management | 5-15 minutes | As needed | 30-70% pain reduction |

| Tissue Regeneration | 2-10 minutes | 2-3x weekly | Enhanced collagen production |

| Dermatological Conditions | 1-5 minutes | Variable | Improved skin texture and healing |

Safety Considerations and Contraindications

Is Cold Plasma Safe for All Patients?

Cold plasma therapy is generally considered safe when performed with properly calibrated equipment and appropriate protocols. However, certain precautions must be observed[10].

Safe for most patients when:

- Treatment parameters are properly controlled

- Exposure time remains within recommended limits

- Equipment meets medical device standards

- Trained professionals administer treatment

Contraindications include:

- Pregnancy and breastfeeding

- Active cancer in treatment area

- Pacemakers or electronic implants

- Severe immunocompromised conditions

- Open wounds near vital organs

Side Effects and Risk Management

Clinical studies report minimal adverse effects with cold plasma therapy. The most common side effects include[11]:

- Mild skin irritation: Temporary redness or tingling

- Transient discomfort: Brief stinging sensation during treatment

- Dryness: Temporary reduction in skin moisture

- Ozone sensitivity: Rare allergic reactions to ozone production

Proper risk management involves:

- Pre-treatment skin assessment

- Gradual dose escalation

- Continuous monitoring during treatment

- Post-treatment follow-up care

How Does Cold Plasma Compare to Laser Therapy?

Cold plasma offers several advantages over traditional laser treatments:

Treatment Mechanism Differences

Cold Plasma:

- Biochemical interaction with tissues

- Multiple therapeutic agents simultaneously

- Non-thermal tissue modification

- Broad-spectrum antimicrobial effects

Laser Therapy:

- Photochemical and thermal effects

- Single wavelength energy delivery

- Controlled thermal tissue damage

- Limited antimicrobial activity

Clinical Outcomes Comparison

Research comparing cold plasma to laser therapy shows comparable efficacy with improved safety profiles. A randomized controlled study found that cold plasma was as effective as Nd:YAG laser for skin rejuvenation, with less discomfort and better hydration outcomes[12].

Cost and Accessibility

Cold plasma systems generally offer:

- Lower initial equipment costs

- Reduced maintenance requirements

- Portable treatment options

- Shorter training periods for operators

Advanced Cold Plasma Technologies

Mirari Cold Plasma Innovation

The Mirari Cold Plasma system represents a significant advancement in cold plasma technology. Developed by General Vibronics and available through miraridoctor.com, this device incorporates several innovative features:

Key Innovations:

- Nitric oxide-based plasma generation: Enhanced biocompatibility

- Dual modality operation: CAP and RES treatment modes

- Temperature control systems: Precise thermal management

- Portable design: Handheld convenience for clinical use

Future Developments

Emerging cold plasma technologies focus on:

- Miniaturized devices: Improved portability and accessibility

- Smart control systems: AI-guided treatment optimization

- Targeted delivery: Enhanced precision for specific conditions

- Combination therapies: Integration with other treatment modalities

Patient-Focused Frequently Asked Questions

What should I expect during cold plasma treatment?

Most patients describe cold plasma treatment as comfortable with minimal sensation. You may experience a mild tingling or warm feeling during treatment. The procedure is typically painless, and most people can return to normal activities immediately afterward.

How long does it take to see results from cold plasma therapy?

Results vary depending on the condition being treated. For wound healing, improvements may be visible within 24-48 hours. Pain relief can occur immediately or within a few treatment sessions. Skin rejuvenation typically shows gradual improvement over 2-4 weeks.

Can cold plasma be used on sensitive skin?

Yes, cold plasma is generally safe for sensitive skin when proper protocols are followed. The treatment operates at body temperature and doesn’t cause thermal damage. However, individuals with extremely sensitive skin should discuss their concerns with their healthcare provider before treatment.

How does cold plasma treatment differ from other wound care methods?

Cold plasma offers unique advantages including simultaneous antimicrobial action, tissue regeneration stimulation, and pain relief. Unlike traditional wound care that may only address one aspect, cold plasma provides comprehensive treatment addressing multiple healing factors simultaneously.

Are there any long-term effects of cold plasma therapy?

Current research indicates no significant long-term adverse effects from properly administered cold plasma therapy. The treatment works with the body’s natural healing processes and doesn’t introduce foreign substances. Long-term studies continue to monitor safety profiles, but current evidence supports the therapy’s safety for repeated use.

Clinical Evidence and Research

Peer-Reviewed Studies

Multiple clinical trials have demonstrated cold plasma’s efficacy across various medical applications. A systematic review of wound healing studies showed consistent positive outcomes, with most trials reporting accelerated healing and reduced infection rates[13].

Regulatory Approval

Cold plasma devices have received regulatory approval in multiple countries:

- FDA clearance: Several devices approved for wound care

- CE marking: European approval for medical applications

- International standards: Compliance with IEC 60601 safety requirements

Ongoing Research

Current research focuses on:

- Cancer treatment applications: Selective tumor cell destruction

- Neurological conditions: Pain management and nerve regeneration

- Cardiovascular applications: Improved circulation and healing

- Dental applications: Periodontal disease treatment

Conclusion

Cold plasma represents a revolutionary advancement in medical technology, offering safe, effective, and versatile treatment options for numerous conditions. From wound healing to pain management, this innovative therapy provides clinicians with a powerful tool that works with the body’s natural healing processes.

The technology’s unique ability to generate multiple therapeutic agents simultaneously, combined with its excellent safety profile, positions cold plasma as a valuable addition to modern medical practice. As research continues and technology advances, cold plasma therapy is likely to expand into new applications, offering hope for patients with challenging medical conditions.

For healthcare providers considering cold plasma therapy, proper training and equipment selection are essential for optimal outcomes. Patients should work with qualified professionals to determine if cold plasma treatment is appropriate for their specific condition and medical history.

Medical Disclaimer: This information is for educational purposes only and should not replace professional medical advice. Always consult with qualified healthcare providers before starting any new treatment.

References

- Plasma-One. (2022). Cold plasma: The leap forward innovation in wound management. https://plasma-one.de/cold-plasma/?lang=en

- Frontiers in Physics. (2020). Cold Plasma in Medicine and Healthcare: The New Frontier in Low Temperature Atmospheric Pressure Plasmas. https://www.frontiersin.org/journals/physics/articles/10.3389/fphy.2020.00074/full

- Braný, D., et al. (2020). Cold Atmospheric Plasma: A Powerful Tool for Modern Medicine. International Journal of Molecular Sciences, 21(8), 2932. https://pmc.ncbi.nlm.nih.gov/articles/PMC7215620/

- El País. (2023). What is cold plasma, and why is it used in some medical treatments? https://english.elpais.com/science-tech/2023-08-31/what-is-cold-plasma-and-why-is-it-used-in-some-medical-treatments.html

- Journal of Wound Management. (2024). Cold Plasma An emerging technology for clinical use in wound healing. https://journals.cambridgemedia.com.au/jwm/volume-25-number-3/cold-plasma-emerging-technology-clinical-use-wound-healing

- Mirari Doctor. (2025). Cold Plasma: A Comprehensive Overview of Technology. https://miraridoctor.com/cold-plasma/

- PMC. (2023). The Regulatory Mechanism of Cold Plasma in Relation to Cell Activity. https://pmc.ncbi.nlm.nih.gov/articles/PMC10138629/

- Vietnam Medical Journal. (2024). Investigating Adverse Effects of Cold Plasma in Burns Treatment. https://tapchiyhocvietnam.vn/index.php/vmj/article/view/5055

- Mirari Doctor. (2025). Handheld Cold Plasma Technology. https://miraridoctor.com/product/

- PubMed. (2024). In Vitro Safety Study on the Use of Cold Atmospheric Plasma. https://pubmed.ncbi.nlm.nih.gov/39272983/

- ActivCell Group. (2025). Cold plasma in human medicine. https://activcellgroup.com/en/cold-plasma-in-medicine/

- PubMed. (2022). Efficacy and safety of non-thermal nitrogen plasma versus long-pulsed Nd:YAG laser. https://pubmed.ncbi.nlm.nih.gov/33420853/

- PMC. (2023). The Role of Cold Atmospheric Plasma in Wound Healing Processes. https://pmc.ncbi.nlm.nih.gov/articles/PMC10219374/

Related articles

Made in USA