How is cold plasma produced in modern medical devices? Cold plasma is generated through electrical energy applied to gases at atmospheric pressure, creating a unique ionized state that remains at room temperature while producing highly reactive species for therapeutic applications[1]. This revolutionary technology has transformed medical treatments by offering non-invasive, precise therapeutic interventions without the thermal damage associated with traditional plasma systems.

Cold atmospheric plasma (CAP) represents a breakthrough in medical technology, combining the power of ionized gases with the safety of low-temperature operation. Unlike traditional hot plasma that requires extreme temperatures, cold plasma maintains tissue-safe temperatures while delivering potent therapeutic effects through reactive oxygen and nitrogen species.

Understanding Cold Plasma Generation Fundamentals

What Makes Cold Plasma Different from Hot Plasma?

Cold plasma, also known as non-thermal plasma, operates on fundamentally different principles than conventional hot plasma systems. The key distinction lies in the temperature differential between electrons and heavy particles within the plasma state[2].

In cold plasma systems, electrons reach temperatures exceeding 10,000K while neutral atoms remain at room temperature. This temperature imbalance creates a unique therapeutic environment where high-energy electrons can interact with biological tissues without causing thermal damage[3].

The production of cold plasma requires precise control of electrical energy delivery to maintain this non-equilibrium state. Modern medical devices achieve this through sophisticated power management systems that regulate voltage, frequency, and pulse duration to optimize therapeutic outcomes while ensuring patient safety.

Core Components Required for Cold Plasma Production

Successful cold plasma generation depends on several critical components working in harmony:

| Component | Function | Medical Application Impact |

|---|---|---|

| Power Supply | Provides controlled electrical energy for gas ionization | Determines plasma intensity and therapeutic depth |

| Electrodes | Apply electric fields to target gases | Controls plasma distribution and treatment precision |

| Dielectric Materials | Prevent arcing and maintain plasma stability | Ensures consistent, safe energy delivery |

| Gas Flow System | Manages gas composition and flow rates | Optimizes reactive species production |

These components must be precisely calibrated to produce cold plasma that meets medical-grade standards for safety and efficacy. The integration of these elements determines the quality and therapeutic potential of the generated plasma.

Primary Methods of Cold Plasma Production

Dielectric Barrier Discharge (DBD) Technology

Dielectric barrier discharge represents the most widely used method for producing cold plasma in medical applications. This technique generates plasma between two electrodes, with at least one covered by a dielectric material such as glass or ceramic[4].

The DBD process begins when high-voltage alternating current is applied across the electrode gap. As voltage reaches the breakdown threshold, gas molecules ionize, creating plasma. The dielectric barrier serves a crucial role by limiting current flow and preventing arc formation, which maintains the plasma in its non-thermal state.

Key advantages of DBD technology include:

- Operation at atmospheric pressure without vacuum requirements

- Uniform plasma distribution across treatment surfaces

- Excellent control over plasma parameters

- Cost-effective implementation for medical devices

The DBD method has proven particularly effective for surface treatments and wound healing applications, where controlled, gentle plasma exposure promotes tissue regeneration without thermal damage.

How Is Cold Plasma Produced Through Corona Discharge?

Corona discharge offers another reliable method for cold plasma production, particularly suited for targeted therapeutic applications. This technique utilizes sharp electrodes to create intense electric fields that ionize surrounding gases[5].

When voltage is applied to a pointed electrode, the electric field concentrates at the tip, creating conditions for gas breakdown. The resulting plasma forms a corona-like pattern around the electrode, producing reactive species that can be directed toward treatment areas.

Corona discharge systems excel in applications requiring:

- Precise plasma targeting

- Variable treatment intensity

- Minimal gas consumption

- Compact device design

This method has found particular success in dermatological applications where localized treatment is essential for optimal outcomes.

Microwave Plasma Generation Systems

Microwave plasma generation represents an advanced approach to cold plasma production that offers exceptional control and efficiency. This method uses electromagnetic waves in the microwave frequency range to energize gases and create plasma[6].

The microwave approach works by directing electromagnetic energy into a gas-filled chamber. The microwaves accelerate electrons within the gas, which then collide with neutral molecules, causing ionization and plasma formation. This method provides several distinct advantages:

Technical Specifications for Microwave Plasma Systems:

| Parameter | Range | Medical Benefit |

|---|---|---|

| Electron Density | 10¹⁰ – 10¹² cm⁻³ | High therapeutic species concentration |

| Electron Temperature | 1 – 10 eV | Optimal energy for biological interactions |

| Gas Temperature | 300 – 1000 K | Safe for direct tissue contact |

| Power Efficiency | 70-90% | Reduced treatment costs and energy consumption |

Microwave plasma systems offer superior scalability and can be adapted for various medical applications, from wound healing to cancer treatment protocols.

Advanced Cold Plasma Production Technologies

Atmospheric Pressure Plasma Jets

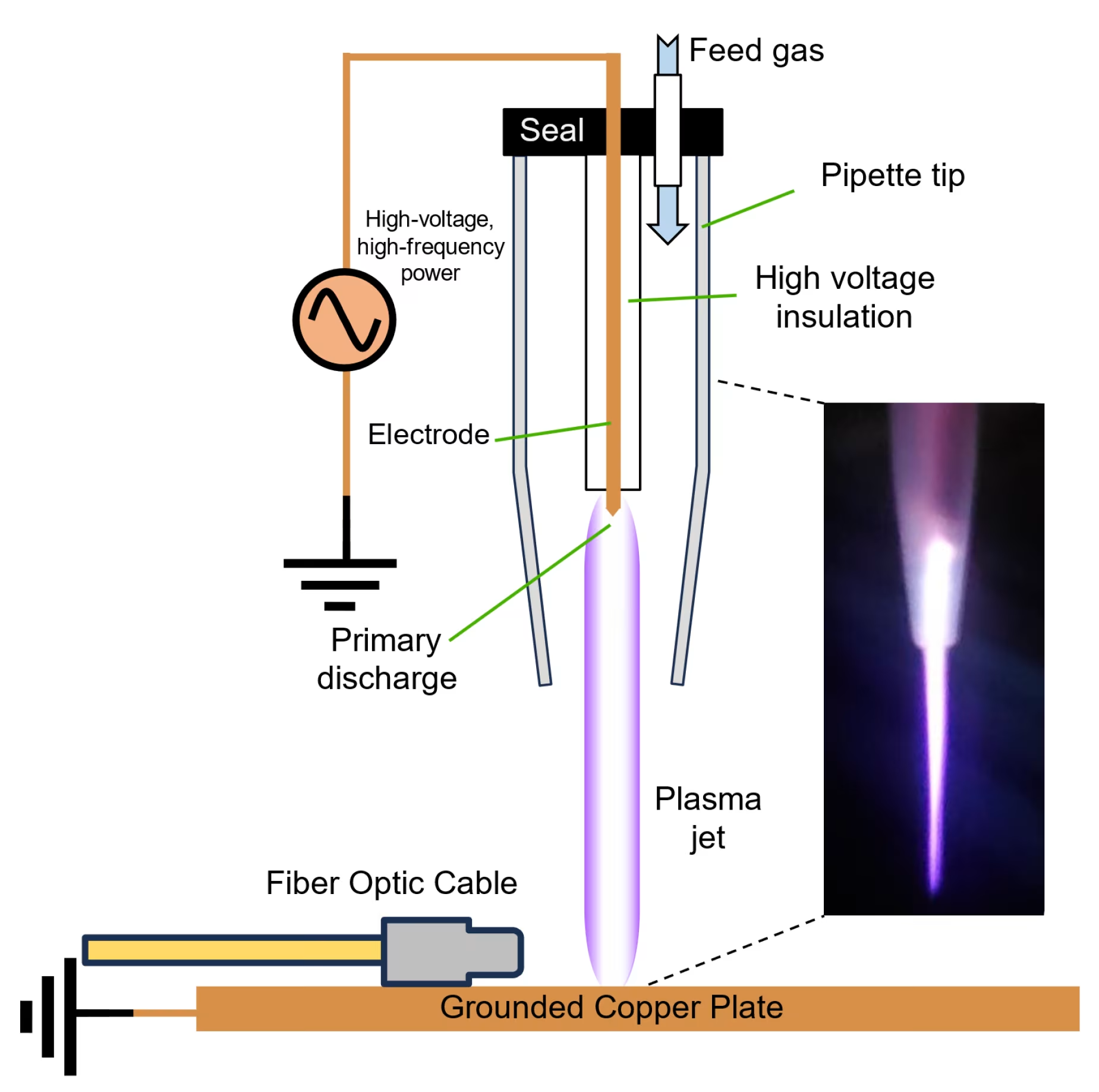

Atmospheric pressure plasma jets represent a sophisticated evolution in cold plasma production technology. These systems generate plasma within a confined space and direct the ionized gas through a nozzle toward the treatment target[7].

The production process involves creating plasma inside a capillary or tube using various electrode configurations. The plasma is then carried by gas flow to the treatment site, allowing for precise application without direct electrode contact with tissues.

Key features of plasma jet technology include:

- Remote plasma delivery capability

- Adjustable treatment distance

- Minimal heat transfer to tissues

- Excellent penetration control

This technology has proven particularly valuable for treating sensitive areas where direct electrode contact would be inappropriate or uncomfortable for patients.

Innovative Nitric Oxide-Based Cold Plasma Systems

One of the most significant advances in cold plasma production involves the development of nitric oxide-based systems. The Mirari Cold Plasma device, developed by General Vibronics and commercialized by Mirari Doctor, represents a breakthrough in this technology by utilizing nitric oxide (NO) instead of traditional reactive oxygen species (ROS) for therapeutic effects[8].

This innovative approach to cold plasma production offers several advantages:

- Enhanced biocompatibility through NO-mediated pathways

- Reduced oxidative stress compared to ROS-based systems

- Improved tissue healing through vasodilation effects

- Better patient tolerance and comfort

The Mirari system demonstrates how modern engineering can optimize cold plasma production for specific therapeutic outcomes while maintaining the highest safety standards.

Clinical Applications and Production Considerations

Optimizing Cold Plasma Production for Medical Use

Medical applications of cold plasma require precise production parameters to ensure both safety and efficacy. The production process must be carefully controlled to generate the appropriate concentration of reactive species while maintaining tissue-safe temperatures[9].

Critical production factors include:

Power Management: Electrical energy must be delivered in controlled pulses to prevent excessive heating while maintaining therapeutic plasma density.

Gas Composition: The choice of carrier gas significantly impacts the types and concentrations of reactive species produced during plasma generation.

Treatment Duration: Production systems must maintain consistent plasma quality throughout extended treatment sessions.

Safety Monitoring: Real-time monitoring of plasma parameters ensures production remains within therapeutic ranges.

How Is Cold Plasma Produced for Different Medical Specialties?

Different medical applications require tailored approaches to cold plasma production. Dermatological treatments may require surface-optimized plasma with specific reactive species profiles, while wound healing applications benefit from deeper penetrating plasma with enhanced antimicrobial properties.

The production parameters can be adjusted to optimize outcomes for specific conditions:

- Wound Healing: Higher nitric oxide concentrations promote angiogenesis and tissue repair

- Antimicrobial Treatment: Increased reactive oxygen species enhance pathogen elimination

- Pain Management: Controlled plasma density provides therapeutic effects without tissue damage

- Cancer Treatment: Specific reactive species combinations target malignant cells selectively

Modern devices like those available through miraridoctor.com demonstrate how production parameters can be optimized for various therapeutic applications while maintaining consistent safety profiles.

Safety Considerations in Cold Plasma Production

Temperature Control During Cold Plasma Generation

Maintaining appropriate temperatures during cold plasma production is crucial for medical safety. Production systems must incorporate sophisticated thermal management to prevent tissue damage while ensuring therapeutic efficacy[10].

Temperature control mechanisms include:

- Real-time thermal monitoring

- Automated power adjustment systems

- Pulse modulation to prevent heat accumulation

- Advanced cooling systems for continuous operation

These safety features ensure that cold plasma production remains within the narrow temperature range required for therapeutic benefit without thermal injury.

Reactive Species Management in Production Systems

The production of cold plasma generates various reactive species that must be carefully controlled to optimize therapeutic outcomes while minimizing potential adverse effects. Modern production systems incorporate sophisticated monitoring and control mechanisms to maintain optimal reactive species concentrations[11].

Key reactive species produced during cold plasma generation include:

- Hydroxyl radicals (- OH): Powerful antimicrobial agents

- Superoxide anions (O₂- ⁻): Cellular signaling modulators

- Nitric oxide (NO): Vasodilation and healing promoters

- Hydrogen peroxide (H₂O₂): Antimicrobial and healing agents

Production systems must balance these species to achieve desired therapeutic effects while avoiding excessive concentrations that could cause cellular damage.

Future Developments in Cold Plasma Production

Emerging Technologies and Production Methods

Research continues to advance cold plasma production technologies, with new methods emerging that promise enhanced therapeutic capabilities and improved safety profiles. These developments focus on more precise control over plasma parameters and the development of specialized production techniques for specific medical applications[12].

Promising areas of development include:

- Miniaturized production systems for portable medical devices

- Smart plasma generation with AI-controlled parameter optimization

- Targeted species production for specific therapeutic outcomes

- Integrated monitoring systems for real-time treatment optimization

Integration with Digital Health Technologies

Modern cold plasma production systems are increasingly incorporating digital health technologies to enhance treatment precision and patient outcomes. These integrations allow for personalized treatment protocols based on individual patient characteristics and real-time treatment response monitoring.

The future of cold plasma production lies in the development of intelligent systems that can adapt production parameters in real-time based on patient feedback and treatment progress, ensuring optimal therapeutic outcomes for each individual case.

Patient-Focused Frequently Asked Questions

Is cold plasma production safe for all patients?

Cold plasma production for medical use is generally safe when performed with properly calibrated equipment and appropriate safety protocols. However, certain patient populations may require special considerations, including those with pacemakers, pregnant women, and individuals with severe immunocompromised conditions. Always consult with healthcare providers before treatment.

How long does it take to produce therapeutic cold plasma?

Modern cold plasma production systems can generate therapeutic plasma within seconds of activation. Treatment sessions typically last 5-15 minutes, during which the production system maintains consistent plasma quality throughout the entire treatment period.

Can cold plasma production be customized for specific conditions?

Yes, advanced cold plasma production systems allow for parameter customization based on specific medical conditions and patient needs. Factors such as power output, pulse frequency, and gas composition can be adjusted to optimize therapeutic outcomes for different applications.

What makes nitric oxide-based cold plasma production different?

Nitric oxide-based cold plasma production, as utilized in devices like the Mirari Cold Plasma system, focuses on generating therapeutic NO rather than traditional reactive oxygen species. This approach offers enhanced biocompatibility and improved healing outcomes through NO-mediated vascular and cellular pathways.

Are there any side effects from cold plasma production systems?

When properly operated within therapeutic parameters, cold plasma production systems typically produce minimal side effects. Some patients may experience mild skin irritation or temporary redness at treatment sites. Serious adverse effects are rare when production systems maintain appropriate safety standards and treatment protocols.

Conclusion

Understanding how cold plasma is produced provides crucial insight into this revolutionary medical technology. From dielectric barrier discharge to advanced nitric oxide-based systems, cold plasma production continues to evolve, offering increasingly sophisticated therapeutic options for patients and healthcare providers.

The future of cold plasma production lies in continued technological advancement, improved safety protocols, and enhanced therapeutic precision. As production methods become more refined and accessible, cold plasma therapy will likely play an increasingly important role in modern medical treatment across multiple specialties.

For healthcare providers and patients interested in exploring cold plasma therapy options, consulting with qualified medical professionals and utilizing properly certified production systems ensures safe, effective treatment outcomes that harness the full potential of this remarkable technology.

References

- University of Minnesota. (2024). Behind the research: Exploring the potential of cold plasma technology. https://cfans.umn.edu/news/exploring-cold-plasma

- Science.lu. (2018). Cold plasma: What is it and how can it be used? https://www.science.lu/my-research-90-seconds/cold-plasma-what-it-and-how-can-it-be-used

- PMC. (2023). The Regulatory Mechanism of Cold Plasma in Relation to Cell Activity. https://pmc.ncbi.nlm.nih.gov/articles/PMC10138629/

- Mirari Doctor. (2025). How Is Cold Plasma Produced? Ultimate Process Guide. https://miraridoctor.com/how-is-cold-plasma-produced/

- Davitap. (2024). Cold Plasma Technology Overview. https://www.davitap.com/en/technology-and-developments/cold-plasma222

- PMC. (2021). Introduction to the Principles of Cold Physical Plasma. https://pmc.ncbi.nlm.nih.gov/articles/PMC7811668/

- ETFlin. (2024). Cold Atmospheric Plasma: A Noteworthy Approach in Medical Science. https://etflin.com/article/120

- Mirari Doctor. (2024). Cold Plasma: A Comprehensive Overview of Technology. https://miraridoctor.com/cold-plasma/

- PMC. (2021). Cold Plasma Systems and Their Application in Surface Treatments. https://pmc.ncbi.nlm.nih.gov/articles/PMC8036572/

- PMC. (2020). Cold Atmospheric Plasma: A Powerful Tool for Modern Medicine. https://pmc.ncbi.nlm.nih.gov/articles/PMC7215620/

- MDPI. (2024). Cold Atmospheric Plasma Medicine: Applications, Challenges, and Opportunities. https://www.mdpi.com/2571-6182/7/1/14

- MDPI. (2024). The Promising Potential of Cold Atmospheric Plasma Therapies. https://www.mdpi.com/2571-6182/7/2/25

Related articles

Made in USA