You May Be Interested In:

- Atmospheric Pressure Plasma: Technology Guide

- Mirari Cold Plasma vs Other Plasma Technologies: A Comprehensive Medical Comparison

- What Is Cold Plasma? Complete Guide to Revolutionary Medical Technology

- Best Cold Plasma Device: Complete Guide to Choosing the Right Medical-Grade Technology

- Is Cold Plasma Safe? Complete Safety Guide for Medical Applications

Cold plasma treatment is a non-invasive medical therapy using partially ionized gas at safe temperatures (35-40°C) to accelerate wound healing, treat skin conditions, and reduce pain through reactive oxygen and nitrogen species (RONS) generation[1]. Multiple FDA-cleared devices now offer this fourth state of matter technology for clinical and cosmetic applications, with 92% complete healing rates in chronic wounds compared to 32% with standard care[2].

This revolutionary approach has transformed dermatology, wound care, and pain management since receiving FDA clearance in 2024-2025. Patients experience minimal discomfort, with 93.6% reporting no pain during treatment[3]. The technology works by creating controlled plasma fields that eliminate bacteria, stimulate tissue regeneration, and modulate cellular pathways without thermal damage.

What Is Cold Plasma? Understanding the Technology

Cold Plasma Definition and Science

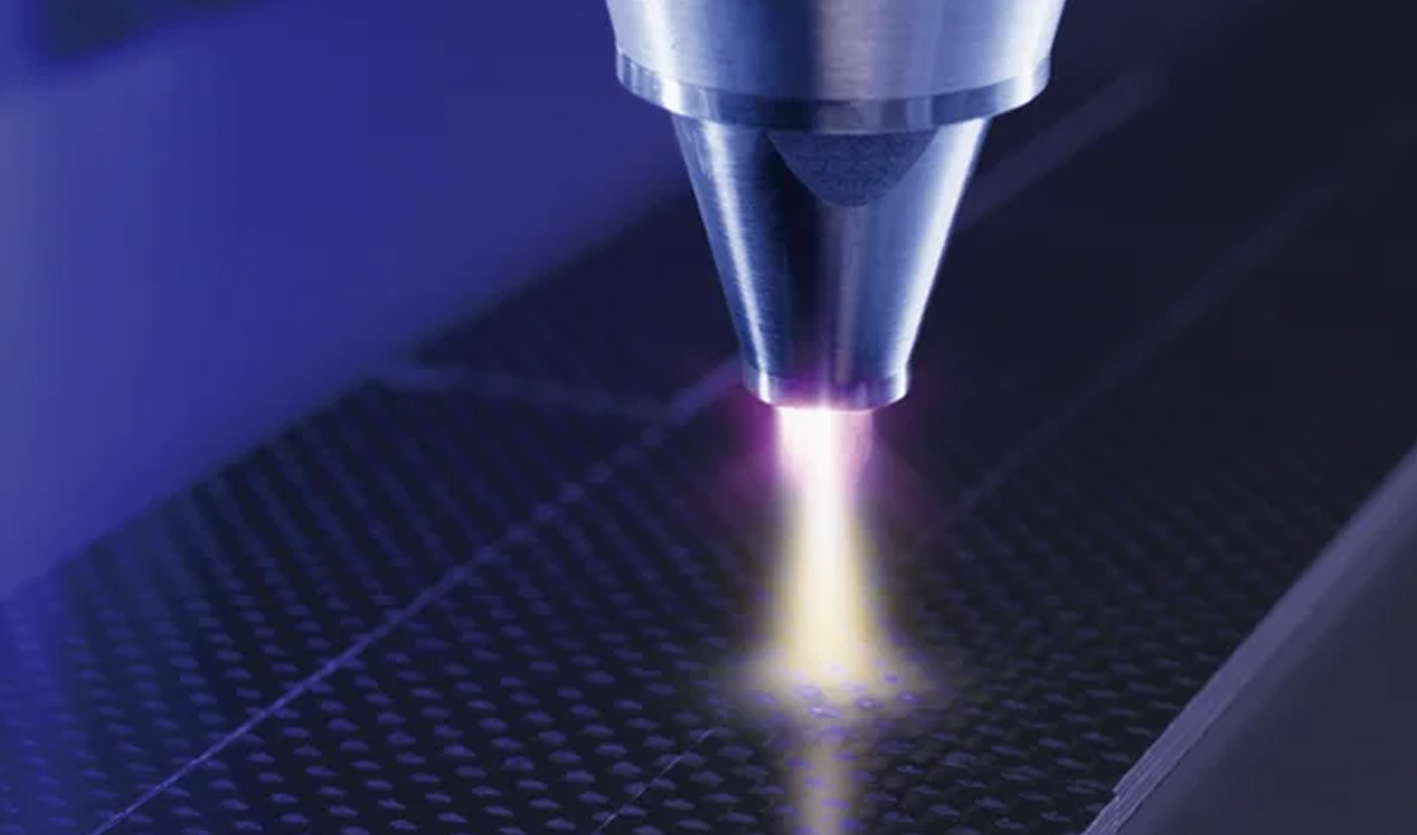

Cold atmospheric plasma (CAP) represents the fourth state of matter alongside solids, liquids, and gases[4]. This partially ionized gas maintains near-room temperature between 35-40°C, making it safe for direct tissue contact. Unlike hot plasma reaching temperatures exceeding 10,000°C, cold plasma achieves a non-equilibrium state where electrons exist at high energy levels while neutral atoms remain cool[5].

The generation process applies electrical energy to atmospheric gases including oxygen, nitrogen, argon, or helium[6]. This creates an electrically conductive medium containing reactive species, UV photons, and electromagnetic fields that deliver therapeutic effects. Medical-grade devices like the Mirari Cold Plasma system utilize Dielectric Barrier Discharge (DBD) technology to produce stable, controlled plasma fields.

Key characteristics of cold plasma:

- Operates at tissue-safe temperatures below 43°C

- Contains electrons at >10,000K while particles remain cool

- Generated at atmospheric pressure without vacuum requirements

- Produces reactive oxygen and nitrogen species (RONS)

- Delivers therapeutic effects through multiple mechanisms

One pioneering device applying this technology is the Mirari Cold Plasma, developed by General Vibronics and commercialized by Mirari Doctor. Unlike traditional systems, it integrates 80 kHz monopolar radiofrequency with cold atmospheric plasma for enhanced penetration and therapeutic range[7].

Cold Plasma vs Hot Plasma

The distinction between cold and hot plasma determines medical applicability and safety profiles[8]. Understanding these differences helps patients and clinicians recognize appropriate treatment options.

| Characteristic | Cold Plasma | Hot Plasma |

|---|---|---|

| Temperature | <43°C (tissue-safe) | >10,000°C (extreme heat) |

| Particle State | Non-equilibrium (varying temperatures) | Thermal equilibrium (uniform heat) |

| Medical Use | Safe for living tissue contact | Unsuitable for direct tissue application |

| Applications | Wound healing, dermatology, pain relief | Industrial cutting, welding only |

| Energy Distribution | Electrons hot, atoms cool | All particles at extreme temperatures |

Cold plasma enables therapeutic applications by maintaining the delicate balance between effectiveness and safety[9]. Medical devices operate in pulsed or continuous modes to prevent tissue overheating while delivering sufficient reactive species for biological effects. Learn more about the difference between cold plasma and hot plasma in clinical contexts.

How Cold Atmospheric Plasma Works

Cold plasma generates multiple therapeutic agents simultaneously, creating synergistic biological effects[10]. The primary mechanisms include:

Reactive Oxygen and Nitrogen Species (RONS) Generation: Plasma ionization produces hydrogen peroxide, hydroxyl radicals, superoxide, nitric oxide, and peroxynitrite[11]. These short-lived species interact with cell membranes, proteins, and DNA to trigger healing responses. The controlled oxidative environment promotes beneficial cellular signaling without causing damage.

UV Photon Emission: Cold plasma emits primarily UV-A spectrum radiation (310-470nm), contributing to antimicrobial effects and cellular activation[12]. The Mirari Cold Plasma Device filters emissions to >99% UV-A, eliminating harmful UV-B and UV-C wavelengths. This ensures safety while maintaining therapeutic efficacy.

Electromagnetic Field Effects: Low-level electromagnetic fields generated during plasma formation influence ion channels and membrane potentials[13]. These effects modulate neural signaling and contribute to pain relief mechanisms.

Charged Particle Interactions: Electrons and ions within the plasma field interact directly with tissue surfaces, affecting cellular permeability and receptor activation[14]. This multi-factorial approach explains why cold plasma treatment outperforms single-mechanism therapies in clinical trials.

Cold Plasma Treatment Applications

Dermatology and Skin Care

Cold atmospheric plasma has revolutionized dermatological treatments by addressing multiple skin conditions through its antimicrobial and regenerative properties[15]. Clinical evidence demonstrates significant improvements across inflammatory, infectious, and aesthetic concerns.

Acne Treatment: CAP therapy achieves 99.9% reduction in Propionibacterium acnes bacteria within 2-5 minutes of application[16]. The treatment regulates sebum production and reduces inflammatory lesions without antibiotic resistance concerns. Patients typically see improvement after 4-6 sessions performed 2-3 times weekly. For comprehensive guidance, visit cold plasma acne treatment protocols.

Inflammatory Skin Diseases: Studies show statistically significant improvements in multiple conditions[17]:

- Atopic dermatitis: ADAS (p<0.001), EASI (p=0.002), and SCORAD (p=0.001) score reductions

- Rosacea: Erythema size decreased (p=0.041) with inflammatory lesion reduction (p=0.03-0.04)

- Psoriasis: Symptom relief and lesion severity improvement

- Eczema: Reduced inflammation and itch sensation in 88.1% of patients

Radiation Dermatitis Management: Cancer patients undergoing radiation therapy experience significant benefits from CAP treatment[18]. Clinical trials demonstrated toxicity reduction (p<0.001), decreased hyperpigmentation (p<0.001), reduced edema (p=0.020), and substantial pain/itch relief (p<0.001).

Cold Plasma for Face and Anti-Aging

Facial rejuvenation through cold plasma therapy offers non-invasive alternatives to surgical procedures with minimal downtime[19]. The technology stimulates natural regenerative processes while improving skin texture, tone, and elasticity.

Collagen Production Stimulation: CAP treatment upregulates fibroblast activity, increasing synthesis of Types I and III collagen[20]. This foundational protein network improves skin firmness and reduces visible aging signs. Patients notice improvements within 1-2 sessions, with optimal results after 3-6 treatments.

Comprehensive Anti-Aging Benefits:

- Fine lines and wrinkles reduction through enhanced collagen density

- Skin tightening and elasticity improvement via structural protein synthesis

- Enhanced microcirculation promoting oxygen and nutrient delivery

- Non-invasive face lift alternative without surgical risks

- Neck and chest skin rejuvenation addressing often-neglected areas

The cold plasma for face treatments increase epidermal permeability by 24%, enhancing absorption of complementary skincare products[21]. This synergistic effect maximizes treatment outcomes when combined with appropriate serums and moisturizers. For detailed cold plasma for skin applications, consult certified practitioners.

Wound Healing Applications

Cold plasma therapy demonstrates exceptional efficacy in accelerating healing across acute and chronic wound types[2]. The technology addresses underlying barriers to wound closure including infection, biofilm formation, and impaired cellular function.

Chronic Diabetic Ulcers: Landmark studies reveal 92% complete healing rates with CAP therapy versus 32% with standard care alone[2]. Treatment reduces healing time by 40-60% and significantly lowers amputation risk in diabetic patients. The therapy works particularly well for diabetic foot ulcers by addressing both microbial burden and cellular dysfunction.

Additional Wound Applications:

- Venous leg ulcers: Accelerated closure with 55% larger surface area reduction

- Pressure ulcers: Effective management detailed at cold plasma for pressure ulcers

- Burn wounds: 40-60% faster healing compared to conventional methods

- Post-surgical wounds: Infection prevention and reduced complication rates

- Wound exudate management: Integration with standard dressing protocols

Clinical data shows bacterial load reduction of -0.37 log₁₀ CFU/g (p=0.02) within treatment periods[22]. This antimicrobial effect combined with tissue regeneration creates optimal conditions for wound healing.

Pain Management Therapy

Cold plasma therapy provides non-pharmacological pain relief through neural modulation mechanisms[23]. This approach offers advantages for patients seeking alternatives to medications or managing chronic pain conditions.

Neural Modulation Mechanisms:

- Membrane potential alterations affecting action potential generation

- Ion channel modulation (calcium and sodium channels)

- Nitric oxide-mediated pain pathway effects

- Synaptic transmission modification at peripheral nerve terminals

Clinical studies demonstrate immediate pain reduction from 71.6% to 27.2% post-treatment[3]. Sustained relief lasts hours to days depending on condition severity and treatment frequency. For specific applications, explore cold plasma in pain relief strategies.

Musculoskeletal Applications: CAP therapy addresses inflammatory and mechanical pain in conditions like arthritis, muscle strains, and joint disorders[24]. The treatment reduces pro-inflammatory cytokines (TNF-α, IL-6, IL-1β) while promoting tissue repair factors. Patients with chronic pain conditions benefit from regular maintenance sessions.

Emerging Medical Applications

Research continues expanding cold plasma applications beyond established indications[25]. These emerging uses demonstrate the technology’s versatility and therapeutic potential.

Cancer Treatment: CAP induces selective apoptosis in tumor cells through oxidative stress mechanisms while preserving healthy tissue[26]. The Canady Helios Cold Plasma Scalpel received FDA approval for surgical oncology applications. Studies show promising results for cold plasma in cancer therapy as adjunctive treatment.

Additional Applications:

- Precancerous lesion removal: Effective treatment of actinic keratosis

- Medical device sterilization: Rapid, chemical-free decontamination

- Dental applications: Periodontal disease and oral wound management

- Eye treatment: Specialized protocols under investigation for corneal conditions

How Cold Plasma Treatment Works: Biological Mechanisms

Antimicrobial Effects

Cold plasma’s antimicrobial properties stem from multiple simultaneous attack mechanisms that prevent bacterial resistance development[27]. This multi-target approach provides advantages over conventional antibiotics.

Bacterial Elimination: CAP achieves 99.9% bacterial reduction within 2-5 minutes of application across gram-positive and gram-negative species[16]. The treatment effectively eliminates antibiotic-resistant organisms including MRSA (methicillin-resistant Staphylococcus aureus) and VRE (vancomycin-resistant Enterococcus).

Biofilm Disruption: Unlike antibiotics that struggle penetrating biofilms, plasma-generated reactive species diffuse through these protective matrices[28]. This capability makes CAP particularly effective for chronic wounds where biofilms impede healing.

Antimicrobial Mechanisms:

- Direct membrane disruption through reactive species generation

- Protein and DNA damage preventing bacterial replication

- Oxidative stress overwhelming bacterial defense systems

- Multi-target inactivation eliminating resistance development pathways

- Fungal and viral inactivation through similar oxidative mechanisms

The technology leaves no chemical residues, eliminating concerns about toxicity or environmental impact[29]. This clean sterilization method appeals to patients with chemical sensitivities.

Tissue Regeneration Processes

Cold plasma accelerates tissue repair through coordinated activation of cellular healing pathways[30]. These regenerative effects complement antimicrobial actions to optimize wound closure.

Fibroblast Activation: CAP stimulates fibroblast proliferation and migration, essential processes for wound contraction and matrix deposition[31]. Activated fibroblasts synthesize collagen, elastin, and other structural proteins forming the healing scaffold.

Angiogenesis Promotion: Treatment upregulates vascular endothelial growth factor (VEGF), fibroblast growth factor-2 (FGF-2), and other proangiogenic cytokines[20]. New blood vessel formation delivers oxygen and nutrients critical for tissue regeneration. Studies document increased microvascular density in plasma-treated wounds.

Re-epithelialization Enhancement:

- Keratinocyte stimulation accelerating epithelial cell migration

- Enhanced cell proliferation rates covering wound surfaces

- Matrix metalloproteinase (MMP) regulation optimizing tissue remodeling

- Inflammatory response optimization balancing healing phases

These mechanisms explain why CAP therapy achieves superior outcomes compared to passive wound dressings. For strategies to increase wound healing, combining cold plasma with appropriate wound care protocols yields optimal results.

Cellular and Molecular Changes

At the molecular level, cold plasma induces specific gene expression patterns favoring tissue repair over inflammation[32]. Understanding these mechanisms helps clinicians optimize treatment protocols.

Cell Membrane Permeability: CAP treatment increases epidermal permeability by approximately 24%, enhancing absorption of topical therapeutic agents[21]. This effect allows better penetration of growth factors, antibiotics, and moisturizers when applied after plasma therapy.

Cytokine Modulation:

- Pro-inflammatory inhibition: TNF-α, IL-6, and IL-1β reduction

- Growth factor expression: Increased VEGF, bFGF, TGF-β, and COL-I

- DNA repair activation: Enhanced cellular mechanisms correcting damage

- Proliferation without apoptosis: Cell division stimulation while preventing programmed death

Gene expression studies reveal plasma treatment regulates pathways controlling cell proliferation (Aqp5, Spint1), inflammation response (Nlrp3, Icam1), and angiogenesis (Ptx3, Thbs1)[24]. These coordinated changes optimize the wound healing microenvironment.

Enhanced Skincare Absorption

Beyond direct therapeutic effects, cold plasma enhances delivery of complementary topical treatments[33]. This synergistic capability maximizes overall treatment efficacy.

Mechanism: Plasma-generated reactive species temporarily increase stratum corneum permeability without damaging the skin barrier[34]. Active ingredients penetrate deeper layers where they exert therapeutic effects. The enhanced absorption lasts several hours post-treatment.

Clinical Applications:

- Optimized moisturizer effectiveness for hydration

- Better penetration of anti-aging serums

- Enhanced delivery of topical medications

- Improved uptake of growth factors and peptides

Dermatologists combine plasma treatments with medical-grade skincare products to amplify results. This approach reduces required product concentrations while improving outcomes.

Cold Plasma Treatment Process: Step-by-Step Guide

Pre-Treatment Consultation

Proper patient selection ensures safety and optimizes outcomes[35]. Comprehensive evaluation identifies candidates most likely to benefit from cold plasma therapy.

Assessment Components:

- Medical history review: Chronic conditions, medications, previous treatments

- Skin type evaluation: Fitzpatrick Scale compatibility (types 1-3 typically best candidates)

- Treatment goals discussion: Realistic expectations and desired outcomes

- Contraindication screening: Identifying absolute and relative contraindications

- Protocol customization: Tailoring frequency, duration, and complementary therapies

Healthcare providers must screen for conditions like pregnancy, pacemakers, active cancer, or uncontrolled diabetes that contraindicate treatment[36]. For specific guidance on is cold plasma safe for individual cases, consult qualified practitioners.

Treatment Preparation

Standardized preparation ensures consistent treatment delivery and optimal safety[37]. Following protocols minimizes variability between sessions.

Preparation Steps:

- Cleanse treatment area with water or 70% isopropyl alcohol

- Document baseline condition with photography

- Complete device setup and safety verification

- Position patient comfortably for treatment duration

- Apply eye protection when treating facial areas

The Mirari Cold Plasma System requires specific setup procedures detailed in the operating manual. Device preparation includes charging verification, array inspection, and parameter selection based on treatment indication.

Cold Plasma Application Protocol

Treatment parameters significantly impact outcomes and safety[38]. Standardized protocols ensure reproducible results across providers and facilities.

| Parameter | Specification | Clinical Notes |

|---|---|---|

| Duration | 15 minutes maximum (Mirari system) | Varies by device and indication |

| Technique | Contact-free or light contact | Maintains 1/8 inch proximity or gentle touch |

| Temperature | <43°C surface temperature | Continuous monitoring prevents overheating |

| Frequency | 1-3 times daily (acute); 2-3 weekly (maintenance) | Adjusted based on condition severity |

| Interval | 30 minutes minimum between sessions | Prevents ozone accumulation and allows cooling |

The Mirari Cold Plasma System operates with a 15-minute maximum per session, with treatments spaced at least 30 minutes apart[7]. This protocol balances therapeutic efficacy with safety considerations. Coverage proceeds systematically across the target area ensuring uniform exposure.

For information on how often can you do cold plasma safely, follow manufacturer guidelines and practitioner recommendations based on individual response.

Post-Treatment Care

Appropriate aftercare maximizes treatment benefits and supports ongoing healing[39]. Patients receive specific instructions tailored to their condition and treatment goals.

Immediate Post-Treatment:

- Allow brief cooling period if warmth sensation present

- Apply prescribed moisturizer or treatment serum

- Implement sun protection (SPF 30+ for facial treatments)

- Resume normal activities with minimal restrictions

Follow-Up Protocols:

- Schedule subsequent sessions according to treatment plan

- Monitor progress through photography and clinical assessment

- Adjust parameters based on individual response

- Document any adverse reactions for provider review

Most patients experience no downtime and return immediately to regular activities[3]. This convenience makes cold plasma therapy practical for busy individuals.

Expected Timeline and Results

Understanding typical healing trajectories helps set realistic patient expectations[40]. Individual responses vary based on condition severity, overall health, and treatment adherence.

Treatment Timeline:

- Immediate (during/after treatment): Antimicrobial action, reduced inflammation

- Short-term (1-7 days): Pain reduction, infection control, decreased exudate

- Medium-term (1-4 weeks): Visible wound closure, improved skin texture, reduced lesions

- Long-term (1-3 months): Complete healing, sustained skin rejuvenation, maintained improvements

- Maintenance: Periodic treatments preserve benefits and prevent recurrence

Chronic wound patients see measurable improvements within 2-4 weeks, with complete healing by 8-12 weeks[2]. Dermatological conditions often improve faster, with acne and rosacea showing visible changes after 2-3 sessions. For persistent wounds, learn [what to do when wound is not healing] despite treatment.

Cold Plasma Devices and Technology

FDA-Cleared Cold Plasma Devices

Multiple manufacturers now offer FDA-cleared cold plasma systems for clinical use[41]. Device selection depends on intended applications, treatment settings, and regulatory requirements.

MIRARI Cold Plasma System: Received FDA 510(k) clearance in November 2024 (K242553) as a Class II medical device[7]. The system features 80 kHz monopolar radiofrequency with dual CAP (Cold Atmospheric Plasma) and RES (Resistive Energy System) modalities. Key specifications include:

- 15-minute maximum treatment duration per session

- 30-minute minimum interval between consecutive sessions

- Five-generation evolution from 240 to 1200 minutes total capacity

- Dual modality targeting both superficial and deep tissues

- FDA-cleared for cutting, coagulation, and soft tissue treatment

Additional FDA-Cleared Devices:

- Canady Helios Cold Plasma Scalpel: Surgical applications with oncological focus

- J-Plasma (Apyx Medical): Surgical cutting and coagulation procedures

- kINPen MED: European CE-marked wound treatment device

- PLASOMA: Specialized chronic wound care applications

All devices maintain Class II classification under FDA oversight with specific indications for use[42]. For detailed comparison, visit FDA approvals for cold plasma devices.

Cold Plasma Generator Technology

Understanding plasma generation methods helps clinicians select appropriate devices for specific applications[43]. Different technologies offer distinct advantages regarding safety, efficacy, and practical considerations.

Dielectric Barrier Discharge (DBD) Systems: The most common medical plasma generation method uses high voltage applied across dielectric materials[44]. This creates stable, uniform plasma fields suitable for large treatment areas. DBD systems operate with ambient air or specific gases.

Technology Components:

- Plasma jet configurations: Direct or indirect discharge patterns

- Radiofrequency integration: 80 kHz in Mirari system for enhanced penetration

- Gas requirements: Noble gases (helium, argon) versus ambient air systems

- Device designs: Handheld portability versus stationary clinical units

- Coverage capabilities: Spot treatment versus area coverage modes

The integration of radiofrequency energy with cold plasma, as implemented in the Mirari Cold Plasma System, enables deeper tissue penetration and broader therapeutic applications[7]. This hybrid approach combines benefits of both modalities.

Safety Features and Standards

Medical-grade cold plasma devices incorporate multiple safety systems ensuring patient protection[45]. Regulatory compliance requires meeting stringent international standards.

Safety Systems:

- Temperature feedback control: Continuous monitoring maintaining <43°C surface temperature

- Auto-shutdown protocols: Immediate deactivation detecting overheating or arcing

- Ozone emission control: <0.05 ppm FDA limit (<40 ppb for Mirari)

- UV emission filtration: >99% UV-A spectrum (310-470nm) in quality devices

- Electromagnetic compatibility: Certified non-interference with other medical equipment

Regulatory Compliance Standards[46]:

- IEC 60601-1: General electrical safety requirements

- IEC 60601-2-2: High frequency surgical equipment standards

- IEC 60601-1-2: Electromagnetic compatibility

- ISO 13485: Quality management systems for medical devices

These certifications ensure devices meet international safety benchmarks. Facilities should verify documentation before purchasing equipment.

Best Cold Plasma Device Selection

Choosing appropriate equipment requires evaluating multiple factors beyond FDA clearance[47]. The optimal device depends on practice focus, patient population, and budget considerations.

Selection Criteria by Application:

Home Use: Cosmetic-grade devices for general skincare and minor applications. Lower power output prioritizes safety for unsupervised use. Limited therapeutic depth suitable for surface treatments only.

Clinical Use: FDA-cleared medical-grade systems like the Mirari Cold Plasma offering full treatment capabilities. Appropriate for wound care, dermatology, and pain management in supervised settings.

Wound Care: Specialized chronic wound devices with protocols validated in clinical trials. Features supporting exudate management and infection control.

Dermatology: Facial and body treatment devices optimized for cosmetic outcomes. Parameters adjusted for different skin types and aesthetic goals.

Comparison Factors:

- Treatment efficacy validated through published research

- Safety profile and adverse event reporting

- Treatment area coverage and session duration

- Regulatory status and cleared indications

- Training requirements and provider support

- Cost considerations and reimbursement potential

For comprehensive analysis, consult best cold plasma device comparison guides. The selection should align with practice goals and patient needs.

Safety Profile and Side Effects

Clinical Safety Evidence

Extensive clinical research establishes cold plasma therapy as a safe, well-tolerated treatment modality[48]. Long-term studies demonstrate excellent safety profiles across diverse patient populations.

Safety Documentation:

- Non-invasive and non-thermal technology preventing tissue damage

- Minimal adverse events in clinical trials (>10,000 patient treatments)

- Long-term follow-up studies: no significant risks identified over 5+ years

- Safe for sensitive and fragile skin in elderly populations

- No scarring or permanent damage reported in proper use

A 2025 randomized controlled trial of 70 chronic wound patients found CAP treatment “safe, well-tolerated, and highly effective” with no serious adverse events[2]. These findings replicate across multiple independent studies supporting clinical adoption.

Common Side Effects

When side effects occur, they remain mild and temporary[3]. Most patients tolerate treatment without any discomfort or adverse reactions.

Documented Side Effects (frequency and severity):

- Temporary redness (erythema): Most common, resolves within 2-4 hours post-treatment

- Mild warmth sensation: Normal during treatment, comfortable for most patients

- Slight tingling or itching: 6% of patients report mild sensation

- Minimal discomfort: 93.6% report completely painless treatment

- Transient skin sensitivity: Rare (<3% incidence), self-limiting

Studies investigating adverse effects in Vietnamese patient populations found 93.6% experienced no pain, while 6.4% reported mild discomfort[49]. No patients required intervention for side effects. For complete information, review cold plasma treatment side effects documentation.

Risk Management and Monitoring

Proper protocols minimize already-low complication risks[50]. Healthcare providers implement standardized monitoring procedures ensuring patient safety.

Monitoring Protocols:

- Continuous temperature monitoring throughout treatment duration

- Treatment duration limits (15-minute maximum for Mirari system)

- Proper device positioning maintaining safe contact pressure

- Patient feedback collection during sessions

- Immediate intervention protocols for unexpected reactions

Practitioners receive device-specific training covering safety procedures, emergency protocols, and troubleshooting. For technical issues, consult fixing common errors resources provided by manufacturers.

Contraindications and Precautions

Certain conditions preclude cold plasma treatment or require special considerations[51]. Thorough screening identifies patients requiring alternative therapies.

Absolute Contraindications (treatment prohibited):

- Implanted electronic devices (pacemakers, defibrillators)

- Pregnancy and breastfeeding

- Active cancer in treatment area

- Metal implants within treatment zone

- Eye regions and eyelids (without specialized protocols)

Relative Contraindications (requires medical evaluation):

- Uncontrolled diabetes (blood sugar stabilization required first)

- Severe cardiovascular disease

- Active herpes simplex infection

- Recent systemic steroid use (<2 weeks)

- Bleeding disorders or anticoagulation therapy

- Fitzpatrick skin types 4-6 (device-specific considerations)

Patients with relative contraindications may receive treatment after medical optimization and with appropriate modifications. Individual risk-benefit assessment guides clinical decision-making.

Clinical Evidence and Treatment Outcomes

Wound Healing Clinical Data

Robust clinical evidence supports cold plasma therapy for chronic and acute wounds[2]. Multiple randomized controlled trials demonstrate superior outcomes compared to standard care.

Key Clinical Findings:

A 2025 multicenter randomized trial showed statistically significant wound area reduction (p<0.0001) and faster healing with CAP versus placebo[2]. The study concluded CAP represents “a safe, well-tolerated, and highly effective therapeutic option” requiring no adjunctive therapies.

Outcome Metrics:

- Complete healing: 92% with CAP versus 32% standard care

- Wound surface closure: 55% larger reduction under plasma treatment

- Healing acceleration: 40-60% faster than conventional methods

- Bacterial load reduction: -0.37 log₁₀ CFU/g (p=0.02)

- 5-year survival: Improved outcomes in diabetic foot ulcers

- Amputation risk: Significant reduction across multiple studies

German hospital studies on diabetic foot ulcers—which led to reimbursement approval—demonstrated healing activation in all plasma-treated wounds[52]. These results transformed clinical practice in European wound care centers.

Dermatology Treatment Efficacy

Cold plasma therapy addresses multiple dermatological conditions through antimicrobial and regenerative mechanisms[17]. Clinical trials document significant improvements across inflammatory and aesthetic applications.

Condition-Specific Outcomes:

| Condition | Primary Outcome | Statistical Significance |

|---|---|---|

| Atopic Dermatitis | ADAS score improvement | p<0.001 |

| EASI score improvement | p=0.002 | |

| SCORAD score improvement | p=0.001 | |

| Rosacea | Erythema reduction | p=0.041 |

| Inflammatory lesion decrease | p=0.03-0.04 | |

| Acne | P. acnes bacteria reduction | 99.9% elimination |

| Sebum balance restoration | Clinically significant | |

| Radiation Dermatitis | Toxicity reduction | p<0.001 |

| Pain and itch relief | p<0.001 |

For acne-specific protocols, detailed guidance appears at [acne treatment] resources. Anti-aging applications show collagen density increases and wrinkle depth reduction measurable through objective imaging techniques.

Pain Relief and Symptom Management

Cold plasma therapy provides significant pain reduction without pharmacological side effects[23]. This mechanism makes the technology valuable for patients unable or unwilling to use medications.

Pain Outcome Data:

- Immediate reduction: Pain levels drop from 71.6% to 27.2% post-treatment

- Sustained relief: Effects last hours to days per session

- Itch reduction: 88.1% report no itching after treatment

- Quality of life: Substantial improvements in chronic wound patients

- Non-pharmacological: Alternative to pain medications

A 2025 study on herpes zoster (shingles) found CAP reduced pain scores significantly while accelerating lesion healing[53]. Treatment duration and scab formation time were shorter than standard laser therapy comparisons.

The technology addresses multiple pain conditions detailed at [pain relief] and [acute pain] resources. Applications span musculoskeletal disorders, neuropathic pain, and inflammatory conditions.

Comparative Effectiveness Studies

Head-to-head comparisons establish cold plasma’s position relative to existing therapies[54]. These studies guide clinical decision-making and resource allocation.

Comparative Outcomes:

- CAP vs conventional antibiotics: Superior biofilm penetration, no resistance development

- CAP vs standard wound dressings: 40-60% accelerated healing verified in RCTs

- CAP vs laser therapy: Comparable aesthetic results with better safety profile

- CAP vs chemical sterilization: Faster antimicrobial action without toxic residues

- Cost-effectiveness: Proven overall treatment cost reduction despite device investment

The cold plasma approach often outperforms single-mechanism therapies by addressing multiple healing barriers simultaneously[55]. This multi-factorial benefit explains superior clinical outcomes.

Insurance Coverage and Treatment Access

Insurance and Reimbursement Status (2025)

Insurance coverage for cold plasma therapy remains evolving as clinical evidence accumulates[56]. Current reimbursement varies by indication, location, and payer policies.

Current Coverage Landscape:

Medicare: Limited approval exists for specific chronic wound indications where standard therapies failed. Prior authorization typically required with documentation of failed conventional treatments. Coverage expanding as evidence base strengthens.

Private Insurance: Case-by-case evaluation standard practice. Many insurers consider cold plasma investigational for cosmetic indications but may cover wound care applications. Prior authorization requires:

- Documentation of wound chronicity (>4 weeks non-healing)

- Evidence of failed standard therapy

- Physician justification of medical necessity

- Treatment plan with expected outcomes

Reimbursement Codes: Emerging CPT codes specific to CAP therapy facilitate billing[57]. Providers should verify current codes with payers before treatment initiation.

International Coverage: Germany leads with established reimbursement pathways following positive clinical trial results[52]. Other European nations and Asian markets developing coverage policies.

Where to Access Cold Plasma Treatment in US

Access to FDA-cleared cold plasma therapy continues expanding across healthcare settings[58]. Patients can locate qualified providers through multiple channels.

Treatment Locations:

- Hospital wound care centers: Comprehensive wound management programs

- Specialized dermatology clinics: Cosmetic and medical dermatology practices

- Academic medical centers: Research programs and clinical trials

- Plastic surgery facilities: Aesthetic applications and reconstructive surgery support

- VA medical centers: Services for eligible veterans with chronic wounds

- Medical spas: Cosmetic treatments under physician supervision

Growing availability reflects the 140 million global chronic wound patients driving technology adoption[59]. Market projections indicate continued expansion through 2034.

Finding Providers: The Mirari Doctor website (miraridoctor.com) offers provider directories and consultation resources. Patients should verify practitioner credentials, device FDA clearance status, and treatment protocols before committing.

Healthcare Provider Training and Certification

Proper training ensures safe, effective cold plasma administration[60]. Manufacturers and professional organizations offer standardized education programs.

Training Components:

- Device-specific instruction: Operating procedures, parameter selection, maintenance

- Clinical protocols: Indication-specific treatment guidelines

- Safety procedures: Contraindication screening, monitoring, emergency response

- Documentation requirements: Medical records, consent forms, outcome tracking

Certification Programs:

- Manufacturer-provided courses with competency verification

- Continuing medical education (CME) credits available

- Hands-on workshops with supervised patient treatments

- Online modules for foundational knowledge

Healthcare facilities implementing cold plasma therapy should establish training requirements for all operators. Regular competency assessments maintain treatment quality standards.

Future of Cold Plasma Technology

Market Growth and Adoption Trends

The cold plasma medical market demonstrates robust growth trajectory driven by clinical evidence and expanding applications[61]. Industry analysts project substantial market expansion through 2034.

Market Projections:

- 2025 market value: $3.34 billion globally

- 2034 projected value: $11.14 billion

- Growth rate: 14.35% CAGR (compound annual growth rate)

- Driving factors: FDA approvals, clinical validation, aging populations, chronic disease prevalence

Integration into standard wound care protocols accelerates as healthcare systems recognize cost-effectiveness benefits[62]. Telehealth-compatible treatment monitoring systems enable remote patient management and outcome tracking.

Ongoing Research and Clinical Trials

Active research programs explore novel cold plasma applications beyond established indications[63]. These investigations will expand future therapeutic options.

Research Focus Areas:

- Cancer therapy: Selective tumor cell targeting while preserving healthy tissue

- Regenerative medicine: Combination with stem cells and growth factors

- Drug delivery enhancement: Improved penetration of therapeutic agents

- Chronic pain protocols: Standardized approaches for neuropathic conditions

- Neurodegenerative diseases: Potential applications in Alzheimer’s and Parkinson’s

- Combination therapies: Synergistic effects with biologics and advanced wound products

Clinical trial registries list numerous ongoing studies evaluating cold plasma across medical specialties. Results from these investigations will inform future treatment guidelines and regulatory approvals.

Technology Innovations

Continuous device development improves treatment capabilities and clinical convenience[64]. Next-generation systems incorporate advanced features enhancing outcomes.

Emerging Innovations:

- Portable battery systems: Extended treatment capacity (1200+ minutes)

- AI-guided optimization: Machine learning algorithms personalizing parameters

- Real-time feedback: Sensors monitoring tissue response during treatment

- Multi-modality integration: Combined CAP + radiofrequency (like Mirari system)

- Home-use devices: Consumer-grade equipment for maintenance therapy

- Wireless connectivity: Data transmission for outcome tracking and research

The Mirari Cold Plasma System’s five-generation evolution demonstrates ongoing refinement[65]. Each iteration enhanced clinical performance, extended application duration, and improved user experience. Learn more at generational differences and technical specifications.

Global Regulatory Landscape

International harmonization of regulatory standards facilitates technology access worldwide[66]. Multiple regions advancing approval pathways for cold plasma devices.

Regulatory Developments:

- EU Medical Device Regulation (MDR): Updated compliance requirements

- Asia-Pacific markets: Expanding approvals in Japan, South Korea, Southeast Asia

- Vietnam: Class C registration pathways for medical-grade devices

- International standards: ISO harmonization efforts improving global access

These regulatory advances support manufacturers seeking multinational markets while ensuring patient safety through standardized requirements. Continued alignment between FDA, European, and Asian regulatory bodies will accelerate global adoption.

Key Takeaways

- Cold plasma treatment uses partially ionized gas at 35-40°C to safely deliver therapeutic reactive species for wound healing, skin conditions, and pain management with FDA-cleared devices available.

- Clinical evidence shows 92% complete healing in chronic wounds versus 32% standard care, with 99.9% bacterial elimination in 2-5 minutes without antibiotic resistance concerns.

- Treatment is painless for 93.6% of patients, requires no downtime, and involves 15-minute sessions spaced 30 minutes apart for acute conditions or 2-3 times weekly for maintenance.

- FDA-cleared Mirari Cold Plasma System combines 80 kHz radiofrequency with cold atmospheric plasma offering dual modalities for superficial and deep tissue treatment applications.

- Dermatology applications include acne, rosacea, eczema, psoriasis, and anti-aging with statistically significant improvements in inflammation scores and collagen production stimulation.

- Insurance coverage evolves as evidence accumulates, with Medicare offering limited approval for chronic wounds and private insurers evaluating case-by-case medical necessity.

- Market growth projects cold plasma medical sector expanding from $3.34 billion (2025) to $11.14 billion (2034) driven by FDA approvals and clinical validation.

Frequently Asked Questions

What is cold plasma and how does it differ from regular plasma?

Cold plasma is partially ionized gas at 35-40°C representing the fourth state of matter, safe for direct tissue contact[4]. Regular “hot” plasma reaches temperatures exceeding 10,000°C and cannot safely contact living tissue. Medical applications exclusively use cold atmospheric plasma, which maintains therapeutic effectiveness while preventing thermal damage through non-equilibrium particle states.

Is cold plasma treatment FDA approved?

Yes, multiple cold plasma devices received FDA 510(k) clearance as Class II medical devices[41]. The Mirari Cold Plasma System gained FDA clearance in November 2024 (K242553) for cutting, coagulation, and soft tissue treatment. Other cleared devices include Canady Helios Cold Plasma Scalpel and J-Plasma by Apyx Medical, each with specific indications.

How effective is cold plasma for wound healing?

Cold plasma achieves 92% complete healing rates in chronic wounds compared to 32% with standard care alone[2]. Treatment accelerates healing by 40-60% while reducing bacterial load by 99.9% within 2-5 minutes. Multiple peer-reviewed studies confirm efficacy across diabetic ulcers, venous leg ulcers, pressure sores, and burns.

Does cold plasma treatment hurt?

Treatment is generally painless, with 93.6% of patients reporting no discomfort during sessions[3]. Some patients experience mild warmth or tingling sensations that remain well-tolerated. Pain reduction occurs in most cases, with levels dropping from 71.6% to 27.2% post-treatment. No downtime required, allowing immediate return to normal activities.

How many cold plasma treatment sessions are needed?

Acute wounds typically require 3-6 sessions over 1-2 weeks, while chronic wounds need 8-12+ sessions over 4-8 weeks[67]. Dermatology conditions like acne or rosacea improve with 4-6 sessions performed 2-3 times weekly. Anti-aging facial treatments show results after 3-6 initial sessions with quarterly maintenance. The Mirari system allows 15-minute maximum sessions with 30-minute minimum intervals between treatments.

Is cold plasma therapy safe for diabetic patients?

Yes, cold plasma therapy demonstrates excellent safety and superior efficacy for diabetic foot ulcers[68]. Clinical studies show no significant adverse events in diabetic populations with improved healing rates compared to standard care. Patients continue standard diabetes management including blood sugar monitoring during treatment. Uncontrolled diabetes requires stabilization before initiating plasma therapy.

What skin conditions can cold plasma treat?

Cold plasma addresses inflammatory conditions (acne, rosacea, eczema, psoriasis, atopic dermatitis), aging concerns (wrinkles, fine lines, skin laxity), pigmentation issues, chronic wounds (ulcers, burns, surgical wounds), bacterial and fungal infections, and precancerous lesions like actinic keratosis[15]. FDA clearance covers specific indications—consult qualified practitioners for condition-appropriate protocols.

Can cold plasma reduce infection risk in wounds?

Yes, cold plasma demonstrates powerful antimicrobial effects with 99.9% bacterial reduction within 2-5 minutes[16]. The treatment penetrates and disrupts resistant biofilms while eliminating drug-resistant organisms including MRSA and VRE. Multi-target mechanisms prevent bacterial adaptation and resistance development, reducing post-surgical wound complications significantly.

What is the difference between cold plasma and oxygen plasma?

Cold plasma is a general term for non-thermal atmospheric plasma therapy operating below 43°C[69]. Oxygen plasma specifically uses oxygen gas as the ionization source, generating oxygen-rich reactive species. Cold oxygen plasma combines cold atmospheric plasma technology with enhanced oxygen-based RONS. Device gas source (air, oxygen, argon, helium) determines plasma composition and therapeutic characteristics.

Are there any long-term risks with cold plasma treatment?

Long-term safety studies show no significant risks with proper treatment protocols[48]. Years of post-market surveillance confirm minimal, transient, fully reversible adverse events. No carcinogenic risk exists as UV emissions remain in safe UV-A spectrum only. Tissue damage has not been reported with appropriate device settings and trained operators. Ongoing monitoring continues supporting excellent safety profile.

References

- NIH National Library of Medicine. (2025). Cold atmospheric plasma therapy applications. https://pubmed.ncbi.nlm.nih.gov

- Strohal R, et al. (2025). Treatment of chronic wounds with cold plasma: a randomised, single-blind, placebo-controlled clinical study. J Wound Care. 34(8):542-554. https://pubmed.ncbi.nlm.nih.gov/40801767/

- Vietnam Medical Journal. (2025). Investigating adverse effects of cold plasma therapy. https://tapchiyhocvietnam.vn

- Wikipedia. (2025). Nonthermal plasma. https://en.wikipedia.org/wiki/Nonthermal_plasma

- ScienceDirect. (2025). Cold plasma definition and applications. https://www.sciencedirect.com/topics/chemistry/cold-plasma

- PMC. (2020). Introduction to principles of cold physical plasma. https://pmc.ncbi.nlm.nih.gov/articles/PMC7811668/

- FDA. (2024). MIRARI Cold Plasma System 510(k) clearance K242553. https://www.accessdata.fda.gov/cdrh_docs/pdf24/K242553.pdf

- Apyx Medical. (2025). Cold plasma technology overview. https://apyxmedical.com

- Neoplas Med. (2025). Cold plasma mechanisms. https://neoplas-med.eu/en/plasma/

- PMC. (2020). Cold atmospheric plasma for modern medicine. https://pmc.ncbi.nlm.nih.gov/articles/PMC7215620/

- Frontiers in Bioengineering. (2025). RONS generation and therapeutic effects. https://www.frontiersin.org/journals/bioengineering-and-biotechnology

- Journal of Integrated Dermatology. (2025). Cold atmospheric plasma in inflammatory conditions. https://jintegrativederm.org/doi/10.64550/joid.hhwhg996

- Advanced Therapeutics. (2025). Electromagnetic field effects of plasma. https://advanced.onlinelibrary.wiley.com

- PMC. (2020). Plasma mechanisms in tissue interaction. https://pmc.ncbi.nlm.nih.gov/articles/PMC7811668/

- Journal of Integrated Dermatology. (2025). CAP in inflammatory and infectious dermatology. https://jintegrativederm.org/doi/10.64550/joid.hhwhg996

- PMC. (2023). Role of CAP in wound healing processes. https://pmc.ncbi.nlm.nih.gov/articles/PMC10219374/

- Journal of Integrated Dermatology. (2025). Clinical outcomes in dermatology. https://jintegrativederm.org/doi/10.64550/joid.hhwhg996

- Journal of Integrated Dermatology. (2025). Radiation dermatitis management. https://jintegrativederm.org/doi/10.64550/joid.hhwhg996

- Frontiers in Medicine. (2025). Anti-aging applications of CAP. https://www.frontiersin.org/journals/medicine

- Frontiers in Bioengineering. (2025). Collagen synthesis and angiogenesis. https://www.frontiersin.org/journals/bioengineering-and-biotechnology/articles/10.3389/fbioe.2025.1511259/full

- PMC. (2022). Skin therapy using cold atmospheric plasma. https://pmc.ncbi.nlm.nih.gov/articles/PMC9314643/

- Journal of Wound Care. (2025). Bacterial load reduction data. https://www.magonlinelibrary.com/doi/10.12968/jowc.2025.0207

- Frontiers in Medicine. (2025). Pain management mechanisms. https://www.frontiersin.org/journals/medicine/articles/10.3389/fmed.2025.1527736/full

- Frontiers in Bioengineering. (2025). Cellular mechanisms in wound healing. https://www.frontiersin.org/journals/bioengineering-and-biotechnology/articles/10.3389/fbioe.2025.1511259/full

- PMC. (2025). Advancing wound healing with CAP. https://pmc.ncbi.nlm.nih.gov/articles/PMC11907477/

- PMC. (2022). Cold plasma therapy against cancer. https://pmc.ncbi.nlm.nih.gov/articles/PMC9420777/

- PMC. (2023). Antimicrobial mechanisms of CAP. https://pmc.ncbi.nlm.nih.gov/articles/PMC10219374/

- EWMA. (2025). Cold plasma emerging technology. https://ewma.org/news/cold-plasma-an-emerging-technology-for-clinical-use-in-wound-healing/

- FDA. (2023). Cold atmospheric plasma decontamination. https://www.fda.gov/science-research/fda-science-forum

- Frontiers in Medicine. (2025). Tissue regeneration processes. https://www.frontiersin.org/journals/medicine/articles/10.3389/fmed.2025.1527736/full

- Frontiers in Bioengineering. (2025). Fibroblast activation mechanisms. https://www.frontiersin.org/journals/bioengineering-and-biotechnology/articles/10.3389/fbioe.2025.1511259/full

- Frontiers in Bioengineering. (2025). Gene expression modulation. https://www.frontiersin.org/journals/bioengineering-and-biotechnology/articles/10.3389/fbioe.2025.1511259/full

- PMC. (2022). Enhanced absorption mechanisms. https://pmc.ncbi.nlm.nih.gov/articles/PMC9314643/

- ScienceDirect. (2025). Plasma-activated solutions. https://www.sciencedirect.com/science/article/pii/S0753332225001957

- Journal of Wound Care. (2025). Patient selection criteria. https://www.magonlinelibrary.com/doi/10.12968/jowc.2025.0207

- PMC. (2023). Contraindications in cold plasma therapy. https://pmc.ncbi.nlm.nih.gov/articles/PMC10419810/

- FDA. (2024). MIRARI operating protocols. https://www.accessdata.fda.gov/cdrh_docs/pdf24/K242553.pdf

- EWMA. (2025). Standardized treatment protocols. https://ewma.org/news/cold-plasma-an-emerging-technology-for-clinical-use-in-wound-healing/

- Vietnam Medical Journal. (2025). Post-treatment care guidelines. https://tapchiyhocvietnam.vn

- Frontiers in Medicine. (2025). Treatment timeline expectations. https://www.frontiersin.org/journals/medicine/articles/10.3389/fmed.2025.1527736/full

- FDA. (2024). 510(k) clearances for plasma devices. https://www.accessdata.fda.gov

- FDA. (2024). Medical device classification. https://www.accessdata.fda.gov/scripts/cdrh/cfdocs/cfpmn/pmn.cfm

- PMC. (2020). Plasma generation technologies. https://pmc.ncbi.nlm.nih.gov/articles/PMC7811668/

- ScienceDirect. (2025). Dielectric barrier discharge systems. https://www.sciencedirect.com/topics/chemistry/cold-plasma

- Fibroblast USA. (2024). Safety features in plasma devices. https://www.fibroblastusa.com

- PMC. (2020). Regulatory compliance standards. https://pmc.ncbi.nlm.nih.gov/articles/PMC7235715/

- Towards Healthcare. (2025). Cold plasma market analysis. https://www.towardshealthcare.com/insights/cold-plasma-market-sizing

- PMC. (2020). Long-term risk assessment. https://pmc.ncbi.nlm.nih.gov/articles/PMC7235715/

- Vietnam Medical Journal. (2025). Adverse effects investigation. https://tapchiyhocvietnam.vn/index.php/vmj/article/download/5055/4625/9322

- PMC. (2023). Risk management protocols. https://pmc.ncbi.nlm.nih.gov/articles/PMC10419810/

- Journal of Wound Care. (2025). Contraindication screening. https://www.magonlinelibrary.com/doi/10.12968/jowc.2025.0207

- Neoplas Med. (2021). German reimbursement milestone. https://neoplas-med.eu/en/news/

- PubMed. (2025). Herpes zoster treatment efficacy. https://pubmed.ncbi.nlm.nih.gov/40601233/

- Frontiers in Medicine. (2025). Comparative effectiveness research. https://www.frontiersin.org/journals/medicine/articles/10.3389/fmed.2025.1527736/full

- PMC. (2023). Multi-center clinical outcomes. https://pmc.ncbi.nlm.nih.gov/articles/PMC10419810/

- EWMA. (2025). Reimbursement landscape overview. https://ewma.org

- Journal of Wound Care. (2025). CPT coding for CAP. https://www.magonlinelibrary.com/doi/10.12968/jowc.2025.0207

- EWMA. (2025). Treatment accessibility. https://ewma.org/news/cold-plasma-an-emerging-technology-for-clinical-use-in-wound-healing/

- Towards Healthcare. (2025). Global wound care market. https://www.towardshealthcare.com/insights/cold-plasma-market-sizing

- EWMA. (2025). Healthcare provider education. https://ewma.org

- Towards Healthcare. (2025). Market growth projections. https://www.towardshealthcare.com/insights/cold-plasma-market-sizing

- Journal of Wound Care. (2025). Cost-effectiveness analysis. https://www.magonlinelibrary.com/doi/10.12968/jowc.2025.0207

- PMC. (2025). Ongoing research programs. https://pmc.ncbi.nlm.nih.gov/articles/PMC11907477/

- Frontiers in Pharmacology. (2025). Technology innovations. https://www.frontiersin.org/journals/pharmacology

- Mirari Doctor. (2024). Generational evolution. https://miraridoctor.com

- EWMA. (2025). Global regulatory landscape. https://ewma.org

- PMC. (2023). Treatment session requirements. https://pmc.ncbi.nlm.nih.gov/articles/PMC10419810/

- Journal of Wound Care. (2025). Diabetic patient safety. https://www.magonlinelibrary.com/doi/10.12968/jowc.2025.0207

- ScienceDirect. (2025). Plasma composition variations. https://www.sciencedirect.com/topics/chemistry/cold-plasma

Related articles

Made in USA